What is a magnetron?

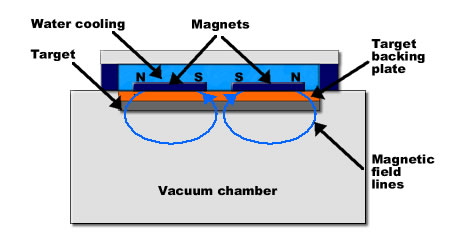

A magnetron is made up of a plate made of the material that will make up all or part of the thin film coating (also known as the target) and magnets positioned behind it in an alternating polarity configuration. See above.

The Magnetron – How is it used to coat tools and components?

A negative voltage of generally -300V or more is provided to the target when power is given to the magnetron. This quickly draws argon ions to the target surface. There are two significant processes that happen when they hit the surface. First, atoms are sputteringly knocked off the target surface at mean kinetic energies of 4 to 6 eV. Click the link to read more about sputtering. The target surface also emits secondary electrons, which are captured by magnetic fields and subject to additional ionising collisions, sustaining the plasma. The glow that is visible below is a result of excited ions relaxing to a lower energy state during the sputtering process and emitting energy in the form of light. A distinct colour will be seen because different materials produce visible light at different wavelengths.

A magnetic field that loops around the inner and outer magnet pole components of the traditional planar magnetron limits the plasma to a closed loop on the target surface.

The Magnetron – Further developments

Magnetron sputtering systems have advanced significantly during the past 15 years or more. The number of ions hitting the substrate during coating in a “conventional” magnetron, which is essential for hard thick coatings, can only be increased by raising the power to the target or decreasing the distance from the target. This issue was solved with the development of the imbalanced magnetron.

Click the links to find out more about the imbalanced magnetron and other advancements in magnetron sputtering, like the “closed field” magnetic arrangement.